Fused Silica (FS)

FS

Fused Silica (FS, oder auch als Quarzglas bekannt) gehört zu den Gläsern, welche sehr hart und transparent sind. Dieses Material besitzt exzellente optische Eigenschaften. Es besteht nahezu zu 100% aus reinem SiO2 und werden bei hohen Temperaturen amorph. Alle Sorten des transparenten FS besitzen nahezu identische optische Eigenschaften. Seine optischen und thermischen Eigenschaften sind besser als andere Glasarten aufgrund seiner Reinheit.

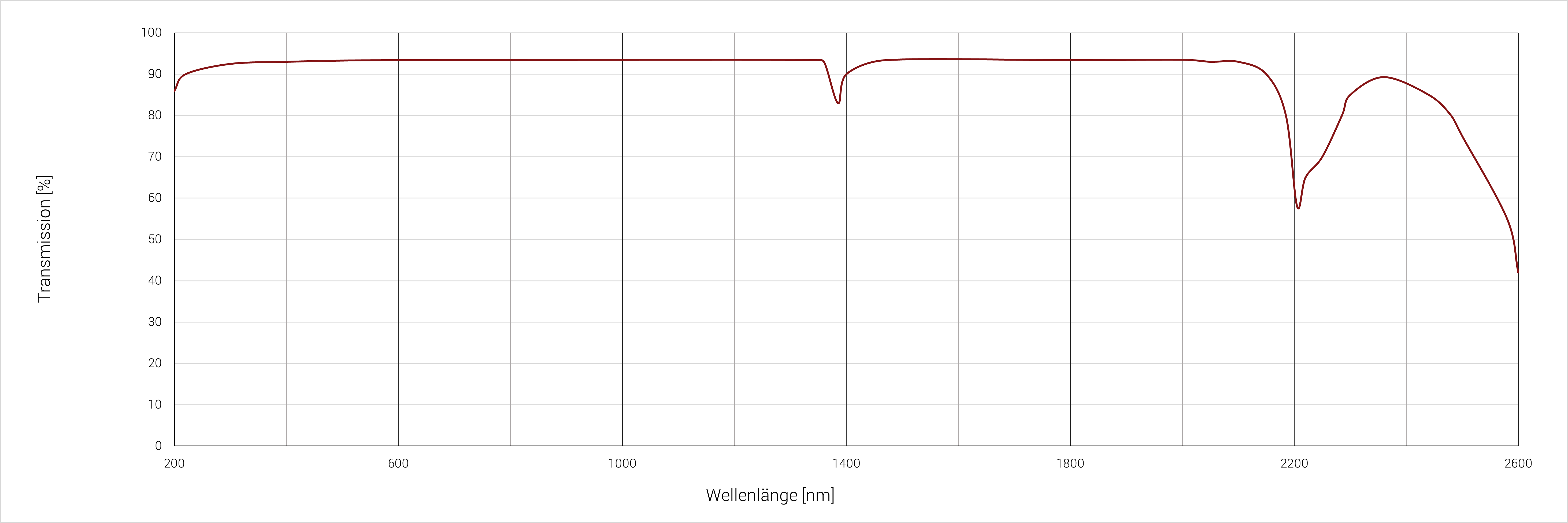

Über einen großen Wellenlängenbereich vom tiefen UV- bis in den IR-Bereich (0,16µm – 3,5µm) ist das Fused Silica transparent. Die UV-Transmission ist hierbei größer als bei den meisten anderen Glassorten. Der Wassergehalt des FS, von dem seine IR-Transmission abhängt, wird bei seiner Herstellung bestimmt. Das UV-grade FS, das thermisch behandelt wird, besitzt ein höherer Wassergehalt sowie weniger metallische Verunreinigung, wodurch es transparenter im UV-Bereich wird. Das elektrisch behandelte IR-grade FS hat mehr metallische Verunreinigungen, sodass seine UV-Transmission auf 250nm begrenzt wird. Dafür besitzt es eine IR-Transmission bis zu 3,6µm. Aufgrund seines geringen thermischen Ausdehnungskoeffizienten (5,5 ∙ 10-7 im Mittel von 20°C bis 320°C) kann FS große Temperaturunterscheide aushalten, ohne dass Risse entstehen. Das FS ist chemisch stabil und ist daher resistent gegenüber den meisten Säuren, ausgenommen Flusssäure (HF) und Phosphorsäure (H2PO4). Wegen seiner hohen optischen Reinheit sie seiner hohen thermischen, chemischen und mechanischen Stabilität ist FS eine exzellente Wahl für viele kritische Anwendungen in hochqualitativen optischen Systemen.

Fused Silica wird zur Herstellung von Fenstern, Prismen, Linsen und anderen optischen Materialien im vom IR- bis in den UV-Bereich verwendet. Wegen seiner geringen thermischen Ausdehnung wird es ebenso als Material für Präzisionsspiegelsubstraten verwendet. Das Quarzglas hat nahezu ideale Eigenschaften zur Herstellung von Oberflächenspiegeln für Teleskope.

Optische Eigenschaften | |

|---|---|

Transmissionsbereich in nm | 160‐3500

|

Brechungsindex @ 486 nm | nf = 1,4632 |

Brechungsindex @588 nm | nd = 1,4586

|

Brechungsindex @656 nm | nc = 1,4565

|

Reflexionsverluste in % an 1 Oberfläche | 7,9 @ 3 µm

|

dN/dT in 1/K | 9,1 · 10-6 @ 1064 nm

|

Physikalische Eigenschaften | |

|---|---|

Dichte in g/cm3 | 2,203

|

Kristallstruktur | amorph |

Blasen/ Einschlüsse | keine |

metallische Verunreinigungen in ppm | 25 ‐ 30 |

Hydroxylgehalt in ppm | 400 ‐ 500 |

Spezifische Wärmekapazität in J/(kg · K) | 703

|

Thermische Leitfähigkeit in W/(m · K) | 1,38

|

Thermische Ausdehnung in 1/K | 0,55· 10-6

|

Erweichungspunkt in °C | 1730

|

oberer Kühlpunkt in °C | 1180 |

unterer Kühlpunkt | 1075 |

max. Betriebstemperatur (kontinuierlich) in °C | 1150

|

max. Betriebstemperatur (begrenzte Dauer) in °C | 1300

|

Dielektrische Konstante @ 1 kHz | a = 10 |

Durchschlagfestigkeit in kV/cm @ 20 °C |

250 ‐ 400 |

Elastizitätsmodul (E) in GPa @ 25 °C | 73

|

Schubmodul (G) in GPa @ 25°C | 31

|

Kompressionsmodul (K) in GPa @ 25 °C | 36,9 |

Biegefestigkeit in MPa @ 25 °C | 50

|

scheinbare Elastizitätsgrenze in MPa | 55

|

Poissonzahl @ 25 °C | 0,17 |

Druckfestigkeit in GPa | 1,1 |

Zugfestigkeit in MPa | 50 |

Knoop Härte in kg/mm2 | 500 |

Spektrale Eigenschaften | |

|---|---|

| |

Probendicke: 2 mm | |