Zinkselenid

Material

ZnSe

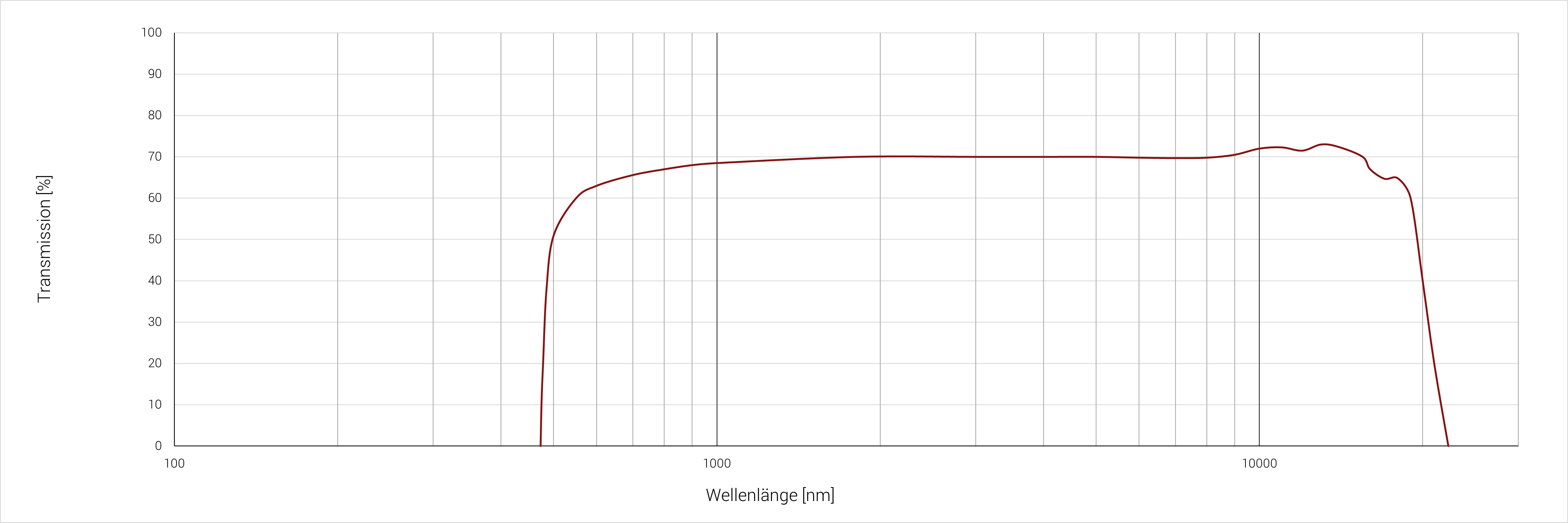

Zinkselenid (ZnSe) ist ein weit verbreitetes Material für optische Komponenten im IR-Bereich. Im Gegensatz zu anderen Materialien wie Ge oder Si, ist Zinkeselenid auch im sichtbaren Bereich transparent. Es besitzt eine Transmission von etwa 70 % im Wellenlängenbereich zwischen 0,6 µm und 20 µm. Das Material ist leicht zu bearbeiten, chemisch inert und hat eine hohe Beständigkeit gegenüber thermischen Schock und Umwelteinflüssen.

ZnSe ist kein natürlich vorkommendes Material und wird mittels chemischer Gasphasenabscheidung (CVD-chemical vapour deposition) gezüchtet.

Im Vergleich zu Zinksulfid (ZnS) ist Zinkselenid weicher und kratzanfälliger. Jedoch hat ZnSe bei einer Wellenlänge von 10,6 µm eine bessere Absorptions- sowie Brechungsindexhomogenität und wird daher in 10,6 µm-Hochleistungslasern eingesetzt. Des Weiteren wird das Material im breiten IR-Bereich für Nachtsichtgeräte sowie Linsen, Fenster uns Prismen verwendet.

Die Bearbeitung von ZnSe muss mit besonderer Vorsicht erfolgen, da Dämpfe, die beim Mahlen und Schleifen des Materials entstehen, giftig sind.

Eigenschaften

Spektrale Eigenschaften

Probendicke: 2 mm